***Quick link to the open access paper: “Foundations of atomic-level plasma processing in nanoelectronics”***

We have just published a topical review paper entitled “Foundations of atomic-level plasma processing in nanoelectronics” in the journal Plasma Sources Science and Technology. This review is part of a two-part collection of papers on Foundations of Low Temperature Plasmas and their Applications with Luís L. Alves (Instituto Superior Técnico, Lisbon, Portugal) and Achim von Keudell (Ruhr Universität Bochum, Bochum, Germany) serving as guest editors.

The aim of this collection of papers is to provide background material on low-temperature plasmas targeting science and engineering graduates – and also other engineers and researchers – who are newcomers to the field. Part I of the collection is dedicated to the fundamental physics of low-temperature plasmas, taking as a basis the content of the lectures presented during the International School on Low-Temperature Plasma Physics: Basics and Applications (Bad Honnef, Germany). By the way, this school started in Eindhoven in 1996 where it was organized for the first couple of years by Prof. Daan Schram, at that time the group leader of what later became the Plasma & Materials Processing (PMP) group (see also this blog post). The papers of part I have been published since 2017.

Part II of the collection is dedicated to the underlying science of the applications of low-temperature plasmas. Our review paper belongs to this part and it falls under the subject “Plasma interface: Controlling the fluxes of ions and reactive species”. A nice feature of the papers published in this collection is that it was stimulated to have researchers from different institutions co-authoring a certain topic. This explains the author list: Karsten Arts, Satoshi Hamaguchi, Tomoko Ito, Kazuhiro Karahashi, Harm Knoops, Adrie Mackus and Erwin Kessels with the affiliations Osaka University, Eindhoven University of Technology, and Oxford Instruments Plasma Technology.

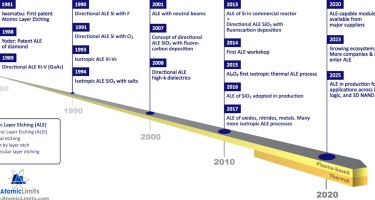

Given the topic of atomic-level plasma processing, the review covers both etching and deposition and is obviously very much about atomic layer etching (ALE) and atomic layer deposition (ALD). Yet, still being plasma-based workhorse methods in the semiconductor industry the paper also discusses reactive ion etching (RIE) and (very briefly) plasma-enhanced chemical vapor deposition (PECVD). Also the methods of ALD and ALE are not introduced in great detail nor is the review a comprehensive overview of what has been reported in the literature. We merely focus on key elementary surface-reaction processes governing the aforementioned plasma processing methods. The emphasis is placed on the latest trends and challenges of the processing techniques from a state-of-the-art application perspective. For example, state-of-the-art 3D NAND memory devices (with up 232 layers for the present-day devices involving double-stack technology) are discussed in terms of the plasma-based processes to fabricate specific structures of the devices: PECVD of the alternating layers, high-aspect ratio etching of channels and slits by RIE, the deposition of dielectric liners and the raising of contact pads by plasma-enhanced ALD, etc.

Well, we are not planning to repeat the contents of the review paper here. The paper is open access and it can be downloaded here for free anyway. We rather highlight some key messages that can be inferred from the paper, either directly or indirectly. Furthermore, we have also included some inspiring and instructive images. Note that the figures of the review paper can be downloaded from the journal page but also from the ImageBase . Additional figures – not included in the review paper – can also be downloaded from the ImageBase.

Message 1: The basic fabrication methods – that formed distinct fields previously – are very much merging.

Not so long ago, the three basic fabrication steps in the manufacturing of semiconductor devices – deposition, lithography and etching – were very distinct fields. I belief that there was even a running joke in which dep guys, litho guys, and etch guys would blame each other when something did not work out well with the processing. The processing issues were at least none of their own business. These times have changed drastically (and luckily enough it is not mostly guys anymore) and the fields have really started to overlap. For example, deposition and etch steps are used in defining and forming the masks by lithography (take the case of self-aligned multiple patterning (SaxP)); film deposition is used during etching (take the case of etching carbon hard masks using ALD-like deposition of SiO2 on the sidewalls during the etch process); and area-selective deposition uses ALE-like cleaning steps to reach a high selectivity etc. The fact that the processing fields are merging has many consequences. It leads to a vastly increased complexity but also yields many new opportunities. Moreover, it makes researchers and technologists with different backgrounds to attend the same conference sessions and workshops to discuss about these topics. Think about the International ALD conference with ALE workshop and the Atomic Scale Processing focus topic at the AVS International Symposium.

Message 2: The current trends in nanoelectronics are all enabled by plasmas

Plasmas are extremely important for the fabrication of chips in the semiconductor industry. Obviously, there are many important processing steps in which no plasmas are involved. Yet without the availability of low-temperature plasmas, the miniaturization of nanoelectronic devices would have been hampered significantlyand would have hit a hard wall many technology nodes ago. There is no doubt about that and it is clear that plasmas will keep enabling the trends in nanoelectronics in the future.

As highlighted in the review paper, plasmas are clearly vital in the field of anisotropic etching and scientific and technological advancements have enabled the etching of very small structures with very challenging aspect ratios. This holds for reactive ion etching and other commonly used plasma-based etch technologies relying on the impact of directional, energetic ions. Yet it also holds for the method of ALE which is currently getting more and more deployed in manufacturing. Moreover, in ALE it is not just about anisotropic etching but also about isotropic ALE in which plasmas can play a role as we elaborated about before here. Plasmas play a similar vital role in the field of deposition. The physical vapor deposition (PVD) method of sputtering employs plasmas to bring (clusters of) atoms in the vapor phase such that they can condense on the substrate surface of interest. In chemical vapor deposition (CVD) plasmas are often used to crack down gaseous precursor molecules such that they become very reactive with the surface even at low temperatures. Plasma-enhanced CVD (PECVD) is a workhorse method in logic and memory devices, particularly for those applications requiring thicker films prepared at lower temperatures (<400 °C). ALD is a CVD-like method and, in addition to thermal ALD, many plasma-enhanced ALD (PEALD) processes are currently used in semiconductor manufacturing. Plasma-enhanced ALD enables the preparation of materials that are difficult to do by thermal ALD, allows for low processing temperatures (<150 °C) and can still reach a very high conformality on demanding 3D surface topologies.

Not addressed in the review paper – but still good to note – is that plasmas also play a vital role in lithography. Here, I don’t refer to methods such as self-aligned multiple patterning (SaxP) involving plasma-based deposition and etch steps, but I refer to the generation of the radiation used in lithography. Gas-discharge lamps were used down to 365 nm radiation and excimer lasers used in generating 248 and 193 nm radiation are also based on gas discharges and hence belong to the field of plasma physics. Moreover, being really vital for the current and future technology nodes, the generation of 13.5 nm extreme-ultraviolet (EUV) radiation takes place by a laser-produced transient tin plasma.

The figure below illustrates a hypothetical process flow in the semiconductor industry and highlights the (potential) use of plasmas in the various steps.

I think it is relevant to realize this importance of plasmas for two reasons. First of all, it is just interesting and fun to know that this “fourth state of matter” – as plasmas used to be labelled in the early work by Sir William Crookes (the word plasma was coined only much later by Irving Langmuir) – are so important for semiconductor device manufacturing. Second, it is important to keep educating people – and especially younger generations – about low-temperature plasma physics. The latter is also directly linked to the aim of this collection of review papers on the Foundations of Low Temperature Plasmas and their Applications as stated in the beginning of this post. However, it is also important to realize that the number of academic groups working on low-temperature plasma physics has significantly declined over the last 2 decades. Evidently, those plasmas are nowadays widescale employed in industry and hence industry is also responsible for related research activities. But obviously, we will need to step up also in academic research to keep enabling the trends in the semiconductor industry and address the big challenges involved (See also A Decadal Assessment of Plasma Science). Hopefully the various “chips acts” that are currently rolled out in the U.S., Europe and Taiwan will also boost the field of atomic level plasma processing in terms of advancement of technology and fundamental understanding.

Message 3: Fundamental understanding of the mechanisms underlying the plasma processing methods is essential.

The key trends indicated in the earlier figure – smaller dimensions, more 3D, more materials, and more integration – illustrate why deep fundamental understanding of the plasma processing methods is essential. Basically, everything is getting more critical, so you need to know exactly what is going on. For example, “more 3D” means that it is becoming more and more difficult to get the right plasma species at the right place, and to remove the reaction products resulting from the plasma-surface interaction. Information on particle transport and surface reaction probabilities is therefore getting increasingly important.

One example highlighted in the paper is the fabrication of 3D NAND memory devices. The contact holes etched for these devices currently have aspect ratios of about 40 to 60. This is already an amazing accomplishment considering the challenges involved, such as aspect-ratio dependent etching, bending, and striation. To reach even higher aspect ratios, it is crucial to understand the ion-surface interaction mechanisms related to these undesired effects, such that they can be controlled. From the deposition side, plasma-enhanced ALD is nowadays used for the deposition of dielectric liners on the vertical slits, where the film conformality and thickness control provided by plasma-enhanced ALD are enabling factors.

In addition to “more 3D”, the inclusion of more materials also calls for a deeper understanding of the mechanisms underlying plasma etching and deposition. Among others, “more materials” demands a better control over aspects such as etch selectivity and material properties. For plasma-enhanced ALD, our paper highlights the impact of ions on the properties of the deposited layer, such as density and crystallinity. This topic has gained considerable attention over the recent years (see also our previous blog post here), which has provided a clearer picture of which knobs govern the influence of ions during plasma-enhanced ALD. Two main knobs appear to be the dose and energy of the supplied ions, as conceptually illustrated in the figure below.

Well, these are some underlying messages that we would like to convey with the publication of the topical review paper. Please don’t hesitate sharing your thoughts and enjoy reading!

1 Comment