Last November the method of atomic layer deposition (ALD) turned 45 years old. The date of November 29, 1974 was the priority date for the first patent in the field of ALD. I considered this a good occasion to share an ALD timeline and animated version of the ALD periodic table on this blog.

The etch counterpart of ALD – atomic layer etching (ALE) – is somewhat younger than ALD. Yet, similarly as for ALD, also for ALE the first report was by means of a patent application: in 1988 a patent application was published with Max Yoder as inventor and with August 31, 1987 as the filing date [1]. As I also have an ALE timeline and an animated version of the ALE periodic table to share, I thought that the anniversary of ALE (around this date ALE has become 32.5 years old… I admit, it is quite a stretch…) was a good occasion to do so by another blog post. So here it is.

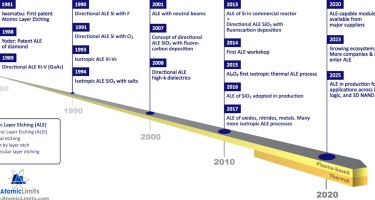

The timeline is quite self-explaining. For the period between the invention of ALE in 1988 and 2014, the timeline is directly based on the one published by Keren Kanarik and co-workers from Lam Research. In 2015, they published a seminal review paper about ALE in the Journal of Vacuum Science and Technology A [2] and the reader is referred to this paper for more information.

Until 2015, most of the papers published on ALE were about directional or anisotropic etching. Therefore, in most cases, plasmas were employed in the second half-cycle of the ALE process such that the directionality of the etch process could be obtained by the energetic ions from the plasma arriving perpendicularly at the substrate’s surface. Note that also several papers report on the use of neutral beams but these are also plasma-generated.

In 2015, however, also the first paper on isotropic etching by Lee and George appeared. In their ACS Nano paper they reported on a thermal ALE process of Al2O3 involving Sn(acac)2 and HF as reactants [3]. This “landmark” has been indicated in the timeline as it triggered many other research efforts for isotropic ALE processes, by the George group but also by many others. Since 2017, a wide set of isotropic ALD processes has been reported.

The difference between anisotropic and isotropic ALE is schematically represented in the figure below. Anisotropic ALE can for example be used for the etching of fins in finFETs whereas isotropic ALE could in principle be used for the isotropic etching (“thinning”) of the nanosheets or nanowires in gate-all-around FETs. This explains the choice for the sketches in the figure. In a recent Nano Letters paper by the George group (University of Colorado Boulder) in collaboration with the Del Alamo group (MIT), thermal ALE was also used for this purpose: sub-5 nm InGaAs gate-all-around FETs were fabricated by a combination of thermal ALE and ALD [4]

By the way, the distinction between anisotropic and isotropic ALE processes makes ALE different from its deposition-counterpart ALD. For ALD, the ability to achieve extremely conformal films even on demanding surface topologies is typically highlighted and processes which don’t yield 100% conformality are typically regarded as poor ALD processes. This difference between ALD and ALE as well as the many similarities between the methods were discussed in our paper Atomic Layer Etching: What Can We Learn from Atomic Layer Deposition? that was also published in 2015 [5]. This paper was part of the JSS Focus Issue on Atomic Layer Etching and Cleaning. In this paper, also several figures similar to the one above are included. You can also find some of these figures in my earlier blog #ALDALE2019 – A preview of my “ALD Innovator Award” plenary presentation at the 19th International Conference on Atomic Layer Deposition.

Coming back to the timeline again, we have not yet discussed the fact that ALE of SiO2 was adopted in production. This news came from a press release from Lam Research referring to the use of ALE for logic devices in the 10 nm technology node. It was also highlighted in another paper by Kanarik and co-workers [6]. The press release discusses applications such as in the etch of self-aligned contacts (SACs), something which was also reported by Honda and co-workers from TEL for their quasi-ALE process [7]. Quasi-ALE is sometimes used for ALE-like processes which are not really self-limiting although not everybody is very strict in this respect. I think there are many processes which are indicated as “ALE” although they are not perfectly self-limiting. Note that the ALE processes for SiO2 go back to the papers by Rauf et al. [8] and Metzler et al. [9].

Now coming to the end of this blog, I would like to present an animated version of the periodic table showing all ALE processes that have been reported in the literature. The animation for ALE is similar to the one for ALD that we posted last November. Please see below! And let me also remind you to keep your new ALE processes to the database. Keeping the database up to date is really a community effort. Thanks to those that have already contributed!

Using the data in the ALE database has also allowed us to update the figure with the number of ALE publications per year as originally published in the review paper by Keren Kanarik and co-workers [2].

I would like to wrap this blog up with a few final comments:

Please don’t forget that the ALE workshop will take place in Ghent, Belgium this year. Together with the ALD conference, this workshop is part of ALD/ALE 2020 which runs from June 28 to July 1. The chairs of the ALE workshop are Harm Knoops, Jean-Francois de Marneffe and myself.

It might also be of interest to know that the ALD Academy has been offering a short course on ALE. This short course can also be given on request at other locations.

The TU/e team members are thanked for their contribution to this blog: Nick Chittock, Tahsin Faraz, Harm Knoops, Vincent Vandalon (thank you big time for the animation!) and Adrie Mackus.

[1] M. Yoder, U.S. patent 4 756 794 (12 July 1988)

[2] Overview of atomic layer etching in the semiconductor industry, K.J. Kanarik, T. Lill, E.A. Hudson, S. Sriraman, S. Tan, J. Marks, V. Vahedi, and R.A. Gottscho, J. Vac. Sci. Technol. A 33, 020802 (2015).

[3] Atomic layer etching of Al2O3 using sequential, self-limiting thermal reactions with Sn(acac)2 and hydrogen fluoride, Y. Lee and S.M. George, ACS Nano 9, 2061 (2015).

[4] In situ thermal atomic layer etching for sub-5 nm InGaAs multigate MOSFETs, W. Lu, Y. Lee, J. C. Gertsch, J.A. Murdzek, A.S. Cavanagh, L. Kong, J.A. del Alamo, and S.M. George, Nano Lett. 19, 5159 (2019).

[5] Atomic Layer Etching: What Can We Learn from Atomic Layer Deposition?, T. Faraz, F. Roozeboom, H. C. M. Knoops and W.M.M. Kessels, ECS J. Solid State Sci. Tech. 4, N5023 (2015)

[6] Atomic layer etching: rethinking the art of etch, K.J. Kanarik, S. Tan, and R.A. Gottscho, J. Phys. Chem. Lett. 9, 4814 (2018).

[7] Benefits of atomic-level processing by quasi-ALE and ALD technique, M. Honda, T. Katsunuma, M. Tabata, A. Tsuji, T. Oishi, T. Hisamatsu, S. Ogawa and Y. Kihara, J. Phys. D: Appl. Phys. 50, 234002 (2017).

[8] A molecular dynamics investigation of fluorocarbon based layer-by-layer etching of silicon and SiO2, S. Rauf, T. Sparks, and P.L.G. Ventzek, V.V. Smirnov, A.V. Stengach, K.G. Gaynullin, and V.A. Pavlovsky, J. Appl. Phys. 101, 033308 (2007).

[9] Fluorocarbon assisted atomic layer etching of SiO2 using cyclic Ar/C4F8 plasma, D. Metzler, R.L. Bruce, S. Engelmann, E.A. Joseph, and G.S. Oehrlein, J. Vac. Sci. Technol. A 32, 020603 (2014).

Leave a Reply